Historically, all of our RCD's/RCBO's have been type AC as the majority of use cases have been with alternating current. However, due to changes with many regulations in EU countries regarding type AC and the increasing popularity of battery based technology, the majority of our distro will now come with type A breakers. This will ensure that our power distrubution equipment meets the standards within the EU and also to accommodate the increasing usage within DC environments. For further technical details, please read the excerpt below.

This explanation focuses on the changes introduced in Amendment 2 to BS 7671:2018 in respect to testing of RCDs (RCCBs & RCBOs as they are more commonly known), it also addresses a number of common questions relating to RCD technology

The early style Residual Current Devices (RCDs) were highly effective protective devices but they have proven to be less reliable in modern buildings as a consequence of DC leakage and DC fault currents caused by electronic equipment. Subsequently, new types of RCD have been developed.

The amendment 2 to BS 7671:2018 in respect to testing of RCDs (RCCBs & RCBOs as they are more commonly known), it also addresses a number of common questions relating to RCD technology.

Regulation 531.3.3 of BS 7671:2018+A2:2022 states that the appropriate RCD shall be selected according to the presence of DC components and AC frequencies. Further, Type AC RCDs shall only be used to serve fixed equipment, where it is known that the load current contains no DC components.

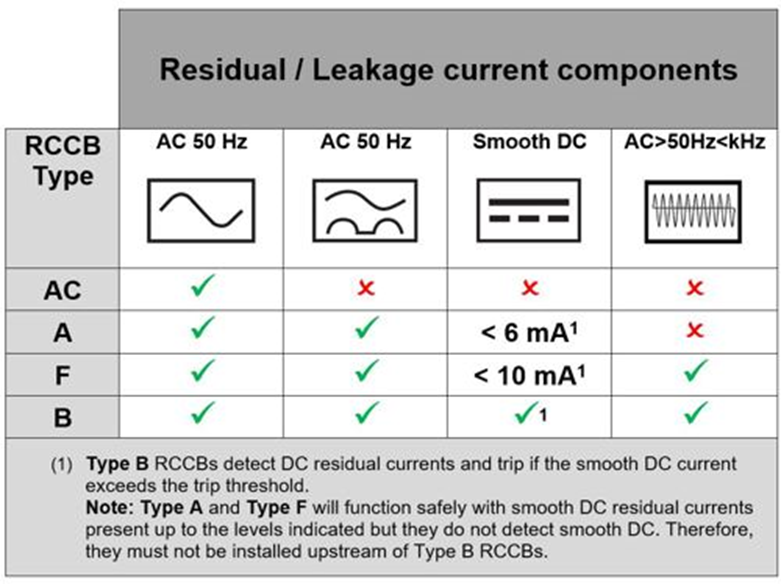

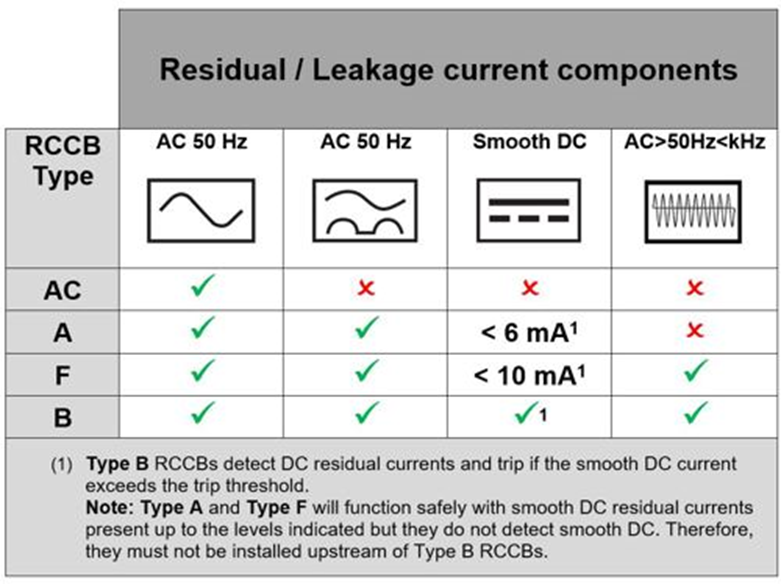

Type AC RCDs are affected by residual DC components and can become desensitized or ‘blinded’ and may not operate within the required time or, in some instances, may not operate at all. Table 1 summarizes the various types of RCD referred in BS 7671:2018+A2:2022 and their resilience to DC components.

Given the prevalence of electronic equipment in most installations, it is difficult to see how the electrical designer will be able to justify the use of Type AC RCDs. Many manufacturers have discontinued Type AC RCDs, preferring to supply type A as a minimum. Therefore, in future it is possible that Type AC RCDs will become obsolete due to lack of demand and Type A RCDs will become the common choice for most new installations, so it is important to understand the changes to the requirements for RCD testing.

See the chart below: